About Our Story

- Raftaar condom is established in 2015. Now Raftaar is most popular brand in india we are succed to win trust of people in india.

- So many people are trust in raftaar.

- we provide superior quality product to our Reliable coustmer.

- Raftaar is giving full safty and security for fight against HIV and AIDS.

- we started our journey with so many struggles.

- now RAFTAAR is available in indias whole medical stores and mall

- Now we feel proud to hear that the raftaar is most trusted and valuable brand in india.

RAFTAAR IS ESTABLISED BY

0

FOUNDING YEAR

0

BRANCH

0

HAPPY COSTUMERS

0

TEAM MEMBERS

0

WORKING COUNTERIES

RAFTAAR CONDOMS - QUALITY CONTROL

- Quality control for condoms is a rigorous and multi-faceted process designed to ensure that every condom manufactured meets stringent international safety and efficacy standards. Given that condoms are medical devices crucial for preventing both unintended pregnancies and the transmission of sexually transmitted infections (STIs), their quality is paramount.

- The process typically involves:

- Raw Material Inspection: Starting with the foundational material, primarily natural rubber latex, but also polyurethane or polyisoprene, a thorough inspection ensures that the raw materials meet specified quality benchmarks for purity, consistency, and elasticity.

- In-process Monitoring: Throughout the manufacturing stages, such as dipping, drying, and vulcanization, continuous monitoring is in place to maintain optimal conditions and detect any deviations that could compromise the product’s integrity.

- Electronic Pinhole Testing (100% inspection): Every single condom undergoes electronic testing. This involves placing the condom on an electrically charged mandrel and passing it through an electrolyte solution. Any pinhole or weak spot will allow an electrical current to pass through, identifying the defective condom, which is then automatically rejected.

- Physical Property Testing (Batch Sampling): A representative sample from each manufacturing batch undergoes a series of destructive and non-destructive tests, including:

- Air Burst Test: Condoms are inflated with air until they burst, measuring their strength and elasticity. International standards require them to hold a minimum volume of air (e.g., 18 liters for ISO 4074:2015), though many manufacturers exceed this.

- Water Leak Test: Condoms are filled with a specified volume of water and suspended for a set period to check for any leaks, indicating holes or weak points.

- Tensile Strength and Elongation Test: Samples are stretched to their breaking point to assess their durability and elasticity.

- Dimensional Checks: Length, width, and thickness are measured to ensure they conform to specified sizes.

- Lubricant Quantity and Quality: The amount and type of lubricant are checked for consistency and suitability.

- Aging and Shelf-Life Testing: Condoms are subjected to accelerated aging tests (e.g., in controlled temperature and humidity ovens) to predict their shelf life and ensure they remain effective until their expiry date. Real-time stability studies are also conducted.

HOW TO MAKE CONDOMS

- The manufacturing of condoms, particularly those made from natural rubber latex (the most common type), is a highly automated and meticulously controlled process to ensure their effectiveness and safety as medical devices. Here’s a step-by-step breakdown.

1. Raw Material Sourcing and Preparation: - Latex Harvesting: The primary raw material is natural rubber latex, a milky sap harvested from rubber trees, primarily in Southeast Asia.

- Pre-Vulcanization and Compounding: The raw latex is processed to remove impurities and then “pre-vulcanized.” This involves adding chemicals (like sulfur, zinc oxide, and antioxidants) to the latex. This initial treatment stabilizes the latex and begins the cross-linking process that gives rubber its strength and elasticity.

2. Dipping Process:

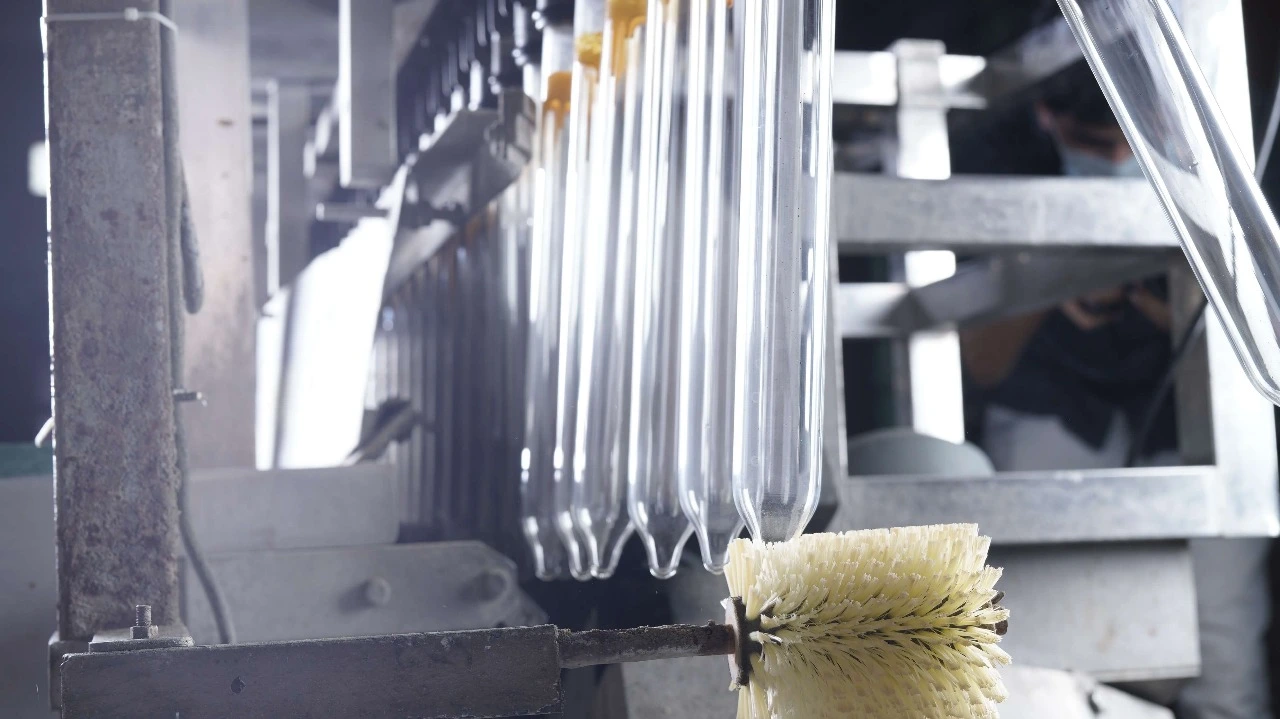

- Former Preparation: Thousands of highly polished glass or metal molds, shaped like the final condom, are continuously moving along a production line. These formers are rigorously cleaned, brushed, and rinsed to ensure no contaminants are present.

- Dipping: The clean formers are slowly dipped into large tanks of the liquid latex compound. The speed of dipping and withdrawal, as well as the concentration of the latex, are precisely controlled to determine the thickness of the condom.

- Drying and Multiple Dips: After the first dip, the formers with a thin latex film are moved through drying ovens. This process is often repeated (typically 2-3 times) with subsequent dips and drying cycles to build up the desired condom thickness and ensure uniformity.

3. Beading and Vulcanization:

- Beading: As the latex film dries, the open end of the condom on the former is rolled or “beaded” by brushes or mechanical means. This creates the characteristic rolled rim that helps the condom stay in place during use.

- Vulcanization/Curing: The beaded condoms on the formers then enter a larger, hotter oven for the final vulcanization process. This high-temperature heating causes the rubber molecules to cross-link significantly, giving the condom its final strength, elasticity, and durability. This is a critical step for the condom’s performance.

4. Leaching and Stripping:

- Leaching: After vulcanization, the condoms are often subjected to a “leaching” process, where they are washed in a solution (e.g., diluted ammonia) to remove excess proteins and other water-soluble chemicals from the latex. This helps reduce potential allergens and improves the feel of the condom.

- Stripping: Once leached and sometimes rinsed again, the finished condoms are carefully stripped off the glass formers, often with the aid of water jets or air pressure.

5. Washing, Powdering, and Drying:

- Washing: The stripped condoms are collected and undergo further washing in large tumbling machines to remove any residual soap deposits or residues from the manufacturing process.

- Powdering/Coating: A powdering solution (often with a pharmacologically safe powder like cornstarch) is applied to prevent the condoms from sticking to themselves and to make them easier to roll and package. Some may also have silicone or other coating agents applied at this stage.

- Tumbling/Drying: The condoms are then tumble-dried in large dryers at controlled temperatures to ensure they are completely dry before quality control.

6. Quality Control and Testing (Crucial Steps):

- Maturation: Condoms are often left to “mature” for a few days to allow the rubber properties to fully stabilize.

- 100% Electronic Pinhole Testing: Every single condom undergoes an individual electronic test for holes. It’s placed on an electrically charged mandrel and passed through an electrolyte. If there’s a hole, an electrical current will flow, and the defective condom is automatically rejected.

- Batch Testing (Sampling): A representative sample from each batch undergoes rigorous destructive and non-destructive tests:

- Air Burst Test: Condoms are inflated with air until they burst, measuring their strength and elasticity (burst volume and pressure).

- Water Leak Test: Condoms are filled with water and suspended to visually check for any leaks.

- Tensile Strength & Elongation: Samples are stretched to their breaking point to assess their durability.

- Dimensional Checks: Length, width, and thickness are measured to ensure they meet size specifications.

- Lubricant Quantity/Quality: If pre-lubricated, the amount and type of lubricant are checked.

- Accelerated Aging Tests: Condoms are subjected to high heat to simulate aging and predict their shelf life.

- Visual Inspection: Human inspectors often conduct visual checks for defects that might not be caught by machines.

7. Lubrication and Packaging: - Lubrication: Condoms that pass all quality control checks are then individually lubricated (if they are lubricated condoms) by an automatic dispenser.

- Foiling/Sealing: Each condom is carefully inserted into its individual foil wrapper. The wrapper is then heat-sealed to create an airtight and light-proof barrier, protecting the condom until use. Batch numbers and expiry dates are printed on the foil at this stage.

- Box Packaging: The individually foiled condoms are then packed into larger consumer boxes, ready for distribution.

- Throughout this entire process, adherence to international standards like ISO 4074 (for natural rubber latex condoms) an